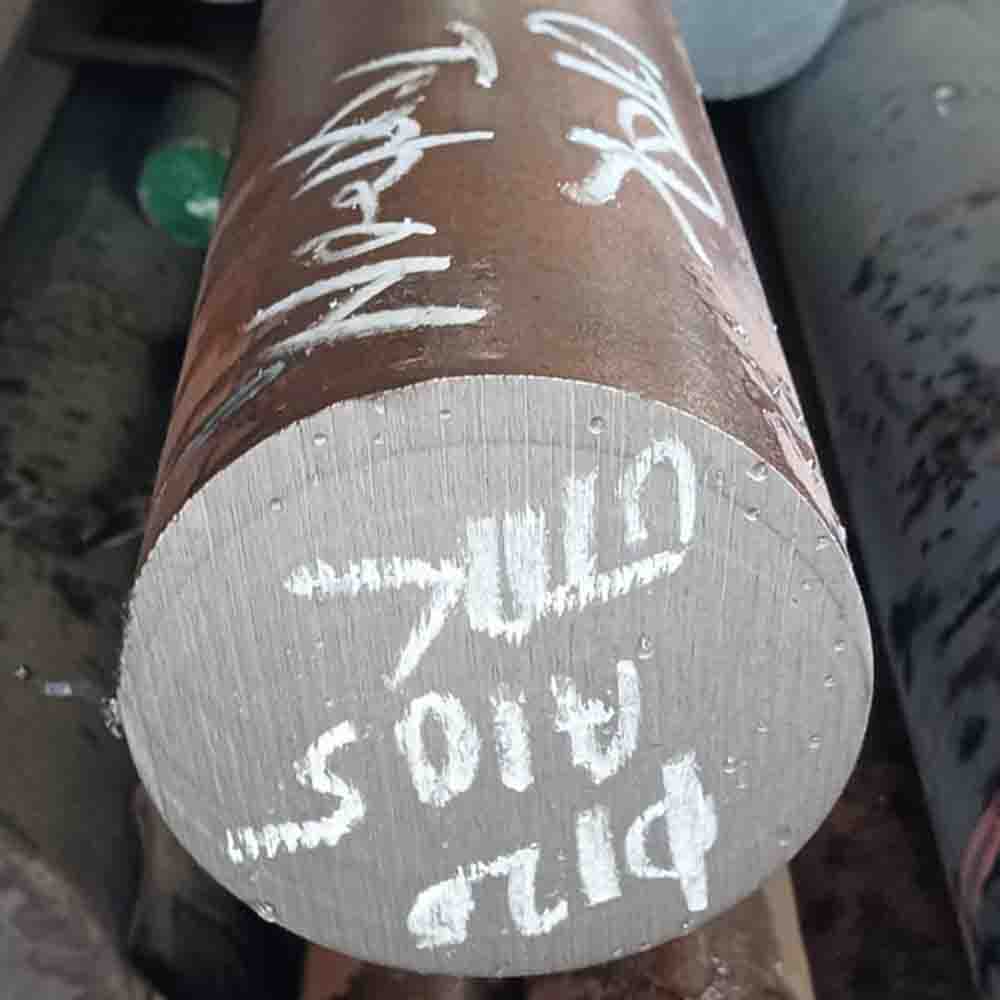

A comprehensive overview of A105 mild steel round bars, covering their composition, properties, applications, processing methods, standards, and surface finish options.

When selecting this material for specific applications, it's essential to consider its properties and suitability for the intended use case, consulting with material engineers or suppliers if necessary.

Chemical Composition (Min-Max):

| Element | Minimum (%) | Maximum (%) |

|---|---|---|

| Carbon (C) | 0.08 | 0.12 |

| Manganese (Mn) | 0.60 | 1.05 |

| Phosphorus (P) | - | 0.040 |

| Sulfur (S) | - | 0.050 |

| Silicon (Si) | - | 0.40 |

Mechanical Properties:

Physical Properties:

Applications:

Processing:

Standards: A105 mild steel round bars typically conform to international standards such as ASTM A105 for carbon steel forgings for piping applications.

Surface Finish: Surface finish options for A105 mild steel round bars include black, peeled, rough turned, or polished, depending on the application requirements.